What you see in the photo above is an apparel display. One of approximately 11,000 that I have constructed since the age of 17 for hundreds of manufacturers.

I've done window displays, wall displays, free standing displays, displays in showcases, apparel displays, jewelry cases, counter tops, point of purchase (POP) displays, book displays, permanent displays, traveling displays, exhibits, exhibitions, kiosks. I've done shadow box displays that were 2 feet wide and I've done them 40 feet wide and 9 feet tall.

|

|

|

| Note my one-off display belt that enabled me to work so fast. It's the only one of it's kind. |

I've built Duratrans-style light boxes 18 inches wide and I've built them 8 feet wide.

I've never used mannequins — always felt they were too easy and a bit of a cop-out (no offense to manequin lovers) — but I have "rigged" plenty of men's suits on forms (called "rigging").

I've built apparel displays for hats, jeans, shorts, knickers, ski pants, hot pants, skirts, dresses, shoes, purses, wallets, bags, belts, tops, tunics, bottoms, robes, nightgowns, bras, panties, thongs, underwear, sports wear, tennis wear, stripper wear, t-shirts, rugby shirts, guru shirts, button down shirts, business suits, overalls, jackets, parkas, leather coats, sport coats, rain coats, sweaters, ponchos, socks, shoes, boots, high heels, sandals, tennis shoes, running shoes, snow shoes, clogs and gloves.

Let's take jean companies for example: I've done showroom displays for Levis, Lee, Wrangler, Sedgefield, Jordache, Calvin Klein, Pierre Cardin, Z. Cavaricci — and many more far too numerous to count.

I use a special leather belt for displays that has all the equipment on it. Spools of 30 gauge (normal) and 22 (heavy) guage wire. Magnets for #17 (small) and #32 (large) steel bank pins. Arrow staples and T-30 staple gun using 3/8ths staples. Scissors, box cutters, and more. Because once you are working in a window or a ladder, it doesn't pay to run out of something. Pins are retained on magnets since one only needs to flip a box of 5,000 pins off the top of a ladder once to realize there has got to be a better way. Strong magnets are the best way.

|

| My display belt was worn backwards with the buckle in the rear, to enable maximum space in front where it is needed. I learned simple leather skills from my hippie sister in the 1960s and make the first version of this belt in late 1970s. |

Displaying clothes from wires is today pretty much a lost art. But from 1964 until the 1990s, this was how most apparel displays were done. At least in the wholesale end of the market. A display artist that used wire in this way was called a "trimmer" — a word that even appeared in many dictionaries and was common lingo in the apparel industry.

Another word you don't hear anymore, and another lost art, was the profession of "rigging." This meant displaying a men's suit on a half form (no head or arms, just a torso). The gaps were filled in with cotton batting. Sheets of cardboard were cut out with scissors and placed under the tails of the coat to stretch out the bottom. The arms were also filled in with padding. When the rigger was done rigging a suit, it looked like it was painted on the form; it was perfect. I did a lot of rigging, but I never learned how to rig like the old guard from the 1940s and '50s. Today, I don't even know if there's anyone alive who knows how to rig a suite. The few riggers I knew were already old even in the 1970s.

The average showroom had 3 to 6 displays. Most of the stores I did had 6. I did 13 trade shows a year with about 20 showrooms per show. That translates into about 1,000 displays a year, not including retail stores. That would have been 10,000 displays in my first 10 years alone.

|

|

| A display from June 2004 for Ronnie Salloway and Fresh Produce. |

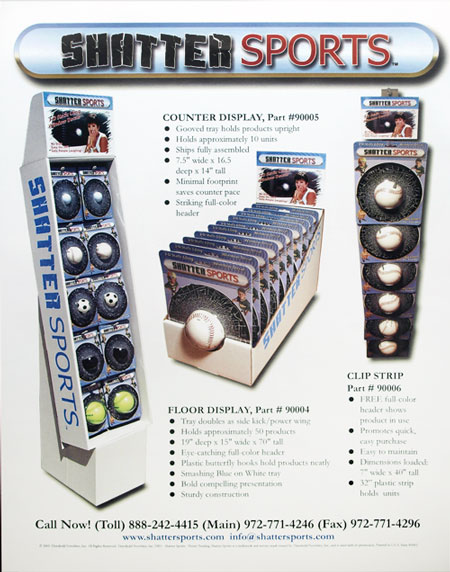

| A few corrugated displays... | |||

|

|

||